SL Centrifugal Separator Introduction

Structure

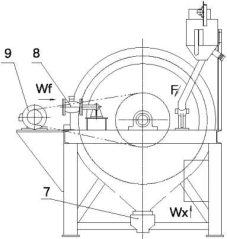

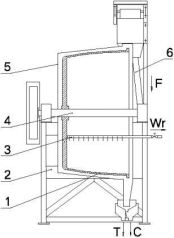

The structure of SL centrifugal separator is shown as below. It consists of centrifugal drum, frame, feeding device, concentrate flushing pipe, rinse pipe, discharge box and so on.

SLon Centrifugal Structure

SLon Centrifugal Structure

1-Centrifugal drum;2-Frame; 3-Rinsing pipe; 4-principal axis; 5-Cover; 6-Feeding device; 7-discharge box; 8-concentrate flushing pipe; 9-Reel moter;

F-Feed C-Concentrate; Wf-Concentrate flushing water; Wr-Rinsing water; Wx-Action

Features

SLon centrifuge separator utilizes different density between the minerals to separate them. It depends on centrifugal force to strength the flow of membrane for separation which greatly improves the processing capacity of the equipment and enables SLon centrifuge separator to collect finer particles. SLon centrifuge separator is efficient in separation, wear-resistant, easy to be operated and maintained.

Application

It’s suitable for separating and collecting fine ferrous minerals, non-ferrous and precious and rare metal minerals, such as magnetite, hematite, specularite, wolframite, tin ore, lead-zinc ore, gold ore, barite and so on, as well as the recovery of fine metal minerals from various mine tailings.

Application of SL Centrifugal Separator in Tungsten Fine Mud

Tungsten fine mud is difficult to recover due to its complex composition, fine particle size, high degree of micro-mudification, unsatisfactory mineral processing technology and mineral processing equipment. SL centrifugal separator has been successfully applied to the separation of tungsten fine mud, which can significantly improve the quality and recovery rate of concentrates, solve the technical problems of tungsten fine mud recovery, and improve resource utilization and enterprise economic benefits.

Jiangxi Xialong Tungsten Mine adopts SL centrifugal separator with one rougher and two cleaner process to recover tungsten from fine mud. The recovery rate of fine mud operation is 11.84% higher than that of shaking table. The final tungsten concentrate grade is increased from 10.83% to more than 17%. The process also achieves good comprehensive recovery of multiple metals. With the improvement of fine mud operation recovery rate, molybdenum concentrates have been increased by 5.4 tons/year and bismuth concentrate increased by 1.8 tons/year year-on-year, creating good economic benefits for the enterprise.

The tungsten grade of a tungsten mine in Fujian is low, with coexistence of wolframite and scheelite, and the ratio of primary ore to weathered ore varies greatly. The original process of the mine adopted “tungsten fine mud flotation rougher – heating cleaner – weak magnetic separation – strong magnetic separation – high frequency shaking table gravity separation” to recover tungsten fine mud. The process flow is complicated, the tungsten recovery rate is low, and the mineral processing indicators do not meet the design requirements.

Through technical transformation, 6 SL centrifugal separators were used to replace the original process. When the feeding tungsten grade was 0.19%, the final tungsten concentrate grade was 22.29%, with the recovery rate of 65.32%.

This process solves the technical problem of tungsten fine mud recovery and has great reference significance for the comprehensive recovery of tungsten fine mud coexisting in black and white tungsten mines.

The original process of Jiangxi Piaotang Tungsten Mine adopted the continuous grinding and shaking table gravity separation process. After technical transformation, the new process adopts the stage grinding – classification-centrifuge separator – one rougher and two cleaner gravity separation process. Under the condition of tungsten ore grade of 0.2%, the concentrate grade of 15% and recovery rate of 75% can be obtained, with the tin concentrate grade of 5% and recovery rate of 60%. Compared with the original process, the tungsten recovery rate increased by 8 percentage points and the tin recovery rate increased by 7 percentage points, with significant economic benefits.

Summary

A large number of industrial applications have shown that compared with traditional gravity separation equipment such as spiral chutes and shaking tables, SL centrifugal separator has the characteristics of high recovery rate, large processing capacity, and wide operating particle size limit. Practice has proved that in the beneficiation of fine-grained iron ore, this equipment can also replace the flotation process of iron ore and be used for the beneficiation of fine-grained iron ore. It has the characteristics of energy saving, environmental protection, and high efficiency. It has innovated the beneficiation process of iron ore and created new technical approaches for the green and efficient development of mines.