Recently, the highly anticipated 3rd China Fine Particle Mineral Processing Technology Conference was grandly opened in Hefei, Anhui Province. The conference, themed “Green and Low-Carbon, Intelligent and Efficient,” was jointly hosted by more than 20 universities and research institutions. It brought together top experts and scholars, as well as key enterprise personnel, to conduct in-depth discussions on five parallel themes: flotation enhancement technology and application, physical separation technology application, mineral processing equipment and intelligentization. The aim was to jointly explore the path of technological innovation and high-quality development in the mining industry. As a leading enterprise in the magnetic separation field, SLon made a stunning appearance with its core technologies and industrialization achievements in fine-grained separation. With its tangible technological breakthroughs and application results, it became the focus of the conference, providing a benchmark solution for the industry to solve the challenges of fine-grained separation.

Fine-grained mineral separation is a key bottleneck restricting the green and efficient development of the mining industry. At this conference, Dr. Xu Jinyue of SLon was invited to give a special report on “SLon series products and their application in fine-grained mineral beneficiation”. With his profound technical expertise and rich application cases, he won the attention of the attendees and provided a key solution for the industry to solve the problem of fine-grained mineral separation.

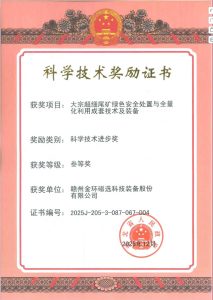

The report focuses on the technological iteration, core advantages, and industrial applications of the SLon series products. After years of technological breakthroughs and iterative upgrades, a product matrix has been formed, encompassing multiple categories including the SLon high-recovery VPHGMS, the SLon high-field-strength VPHGMS, the SJ HEMF, and the SL Centrifugal Separator. These products can meet the separation needs of various fine-grained minerals such as tungsten, tin, red mud, ilmenite, and iron oxide ores. The report highlights three successful application achievements: in the field of red mud iron ore beneficiation, achieving efficient recovery and resource utilization of solid waste resources; in the recovery of tungsten-tin fine mud, significantly improving the enrichment ratio and metal recovery rate; and in the separation of fine-grained ilmenite, minimizing metal loss in tailings and significantly improving titanium resource utilization. It is worth mentioning that these application achievements, based on their outstanding technological innovation and practical value, won the third prize of the 2025 Hubei Provincial Science and Technology Progress Award, gaining authoritative recognition for their technological strength and industry contributions.

At the exhibition, SLon technology demonstration area was bustling with activity. Attendees stopped to inquire and expressed great interest in the innovative equipment technologies and practical application cases, engaging in in-depth discussions.

In the future, SLon will leverage this conference as an opportunity to continuously advance the technological iteration and innovation of its SLon series products, deepen industry-academia-research cooperation with universities and research institutions, focus on the core pain points in the field of fine-grained mineral separation, and launch more green and intelligent equipment and mineral processing processes tailored to industry needs. This will contribute to the high-quality development of the mining industry and the achievement of “dual carbon” goals!