Lepidolite Introduction

With the rapid development of the new energy industry, lithium resources have become a key factor in supporting electric vehicles, energy storage batteries and other fields. As an important source of lithium resources, lepidolite is the main raw material for extracting metallic lithium, lithium carbonate and lithium chemicals, which is widely used in lithium batteries, metallurgy, glass, ceramics, medicine, chemical industry and other fields. Efficient ore dressing technology for lepidolite is crucial. Magnetic separation technology has become the core link in the lepidolite beneficiation process with its unique advantages.

Lepidolite often coexists with magnetic minerals such as hematite and biotite. Magnetic separation technology uses the difference in the magnetic properties of these minerals to separate lepidolite from impurities. Under the action of the magnetic field, impurities with strong magnetism will be attracted by the magnetic force, while lepidolite with weak or no magnetism will not be affected, thereby achieving the purpose of initial enrichment of lepidolite.

Common Lepidolite Selection Process

A complete set of lepidolite magnetic separation process, covering multiple steps such as crushing, grinding, magnetic separation and concentration.

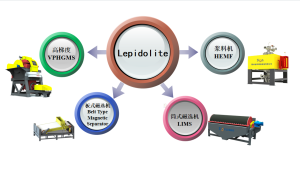

SLon lepidolite purification magnetic separation equipment includes:

Common beneficiation process

- Crushing: The raw ore is crushed to the particle size of less than 12mm using a three-stage and one-closed-circuit crushing and screening process, including coarse crushing, medium crushing and fine crushing and screening. The last stage of the fine crusher and the screen form a closed-circuit operation to control the particle size of the crushed product.

-

Grinding and Classification: Grinding and classification adopts a double closed-circuit process of ball mill, hydrocyclone and high-frequency fine screen. After ball milling, the material enters the hydrocyclone, and the overflow of the hydrocyclone is fed into the high-frequency fine screen. The oversize after screening and the hydrocyclone desilting sand are returned to the ball mill together. The particle size of the product under the high-frequency screen is controlled to be less than 0.15mm, accounting for 60% – 80%.

-

Magnetic separation: The undersize after grinding and classification is subjected to magnetic separation. Weak magnetic separation is used to obtain iron concentrate and magnetic tailings. This can achieve efficient separation of iron concentrate and improve the effect of inevitable ions Fe³⁺on the flotation of lepidolite.

-

Gravity separation: The tailings from magnetic separation are subjected to multiple distribution operations and multiple shaking table gravity separation operations. Generally, two distribution operations and two shaking table gravity separation operations are adopted, and both adopt a one-stage roughing and one-stage scavenging process to obtain tantalum, niobium and tin concentrates, as well as gravity separation tailings and shaking table middlings.

-

Desliming: The gravity separation tailings are subjected to multi-stage desliming cyclone operation, usually 2-stage desliming cyclone operation. The 2-stage cyclone forms a closed-circuit operation to obtain ultra-fine feldspar and cyclone sedimentation sand.

-

Flotation: The cyclone sedimentation is fed into the flotation operation, which is carried out in an environment of pH 7-10. The mass concentration of the roughing pulp is 25%-35%. The flotation reagent contains collector, activator and dispersant. Through flotation, the lepidolite and feldspar can be separated to obtain lepidolite concentrate and flotation tailings.

-

Reselection: The flotation tailings are subjected to high gradient magnetic separation to obtain feldspar and magnetic concentrates. The magnetic concentrates are mixed with the shaking table middlings obtained in the gravity separation step and returned to the grinding and classification step.

SLon Case of a large lepidolite mine in Jiangxi province, China

Taking a large lepidolite mine in Jiangxi as an example, after the introduction of SLon magnetic separation equipment, the efficiency and quality of lepidolite beneficiation have been significantly improved. SLon magnetic separation equipment uses high-performance magnetic materials, which can generate high-intensity and evenly distributed magnetic fields. When the ore pulp after grinding enters the equipment, the magnetic impurities in it, such as hematite, biotite, etc., will be quickly adsorbed on the surface of the magnetic separation components of the equipment by the strong magnetic field force. As the equipment runs, these magnetic impurities adsorbed on the magnetic separation components are taken to the discharge port. Lepidolite, due to its weak or non-magnetic magnetism, passes smoothly through the magnetic field area under the action of the slurry flow, and flows out from the non-magnetic product outlet, thereby realizing the efficient separation of lepidolite and magnetic impurities. After rough separation by SLon magnetic separation equipment, the grade of lepidolite has been increased from 1.2% of the raw ore to 2.8%, laying a good foundation for subsequent concentration operations.

In addition, the unique structural design of SLon magnetic separation equipment optimizes the flow rate and direction of the slurry in the equipment, so that the minerals can be fully separated in the magnetic field, ensuring the stability of the magnetic separation effect. At the same time, the equipment is easy to operate and has a high degree of automation. It can flexibly adjust parameters according to the properties of different ores, effectively reducing labor costs and operating difficulties. Its stable and reliable operating performance and convenient maintenance design reduce downtime, which greatly improve production efficiency and create considerable economic benefits for the company.

After completing the roughing process of magnetic separation, the lepidolite concentrate needs to go through the fine separation process to further remove residual impurities and improve the grade of the lepidolite to meet the requirements of subsequent lithium extraction.

With the continuous growth of the new energy industry’s demand for lithium resources, SLon magnetic separation equipment is also constantly innovating and upgrading. In the future, it will play a greater role in the field of lepidolite magnetic separation and promote the high-quality development of the lepidolite beneficiation industry.