Quartz sand is one of the most widely distributed non-metallic minerals in nature. Its primary component is silicon dioxide (SiO2). Due to its excellent properties such as high hardness, strong chemical stability, and high-temperature resistance, it is widely used in various fields such as industry, construction, and environmental protection. As an expert in mineral processing and magnetic separation, SLon will guide you through a comprehensive understanding of quartz sand, from classification, application, quality requirements, to production and reserves.

I. Classification of Quartz Sand: Precise Categorization by Properties and Applications

There are various ways to classify quartz sand. The core can be divided into three dimensions: purity, particle size, and processing technology. Different categories correspond to different application scenarios.

In terms of purity, quartz sand can be divided into ordinary quartz sand, refined quartz sand, and high-purity quartz sand. Ordinary quartz sand has a SiO₂ content of approximately 90%-95% and contains a lot of impurities, mainly from the crushing and screening of natural quartz stone. Refined quartz sand is purified through processes such as pickling and magnetic separation, raising the SiO₂ content to 99%-99.5%, significantly reducing the impurity content. High-purity quartz sand is the “high-end” quartz sand, with an SiO₂ content of over 99.9%, or even 99.99%. It undergoes a complex purification process to remove trace impurities such as iron, aluminum, and calcium, which is often used in high-end manufacturing.

According to particle size, quartz sand can be divided into coarse sand (0.5-1mm), medium sand (0.25-0.5mm), fine sand (0.125-0.25mm), and ultrafine sand (less than 0.125mm). The particle size selection depends on the specific application. For example, medium and coarse sand is often used in construction, while ultrafine sand is commonly used in the electronics industry.

|

Sieve size |

Standard mesh |

Sieve size |

Standard mesh |

|

4.75mm |

4 mesh |

0.355mm |

45 mesh |

|

4.00mm |

5 mesh |

0.300mm |

50 mesh |

|

3.35mm |

6 mesh |

0.250mm |

60 mesh |

|

2.80mm |

7 mesh |

0.212mm |

70 mesh |

|

2.36mm |

8 mesh |

0.180mm |

80 mesh |

|

2.00mm |

10 mesh |

0.150mm |

100 mesh |

|

1.70mm |

12 mesh |

0.125mm |

120 mesh |

|

1.40mm |

14 mesh |

0.106mm |

140 mesh |

|

1.18mm |

16 mesh |

0.090mm |

170 mesh |

|

1.00mm |

18 mesh |

0.0750mm |

200 mesh |

|

0.850mm |

20 mesh |

0.0630mm |

230 mesh |

|

0.710mm |

25 mesh |

0.0530mm |

270 mesh |

|

0.600mm |

30 mesh |

0.0450mm |

325 mesh |

|

0.500mm |

35 mesh |

0.0374mm |

400 mesh |

|

0.425mm |

40 mesh |

|

Based on the processing technology, quartz sand can be divided into natural quartz sand and artificial quartz sand. Natural quartz sand is directly produced by crushing, which is relatively low-cost. Artificial quartz sand is recycled from raw materials such as quartz sand tailings and waste glass. It combines environmental advantages with cost-effectiveness, which has become a new category in recent years.

II. Quartz Sand Origins and Reserves: Global Distribution with Regional Disparities in Quality and Quantity

The raw material sources of quartz sand are distributed across multiple countries and regions worldwide, with China, the United States, Brazil, and Russia leading the global production. Quartz sand resources in these regions each have their own unique characteristics in terms of output, quality, and application, providing a stable and diverse supply to the global market.

China is one of the world’s largest producers of quartz sand, boasting abundant quartz mineral resources. Its quartz sand is primarily sourced from regions such as Hebei, Shandong, and Jiangsu. Key production areas include Pingshan, Kuancheng, and Yuxian in Hebei Province, as well as Yinan in Shandong Province. Additionally, Fengyang County in Anhui Province and Donghai County in Jiangsu Province are renowned for their rich quartz sand resources. Fengyang County has been designated as a “national 100-billion-yuan silicon industry base” under the state’s key development plan. Preliminary surveys indicate proven high-quality quartz sand reserves of 10 billion tons, with mining areas covering 80 square kilometers. The silica (SiO₂) content in the extracted sand exceeds 99%. Donghai County, hailed as the “Quartz Capital of the East,” possesses quartz reserves of 300 million tons, ranking first in China in both reserve scale and quality.

III. Applications of Quartz Sand: A Versatile Industrial Cornerstone

Quartz sand permeates every facet of industrial production and daily life, with varying purities and particle sizes serving distinct roles.

Construction: Standard medium-coarse quartz sand serves as the core aggregate in concrete, mortar, and insulation materials. Its exceptional strength and stability ensure structural durability.

Water Treatment: Refined quartz sand filters, with high porosity and adsorption capacity, are widely used in potable water and industrial wastewater purification to remove suspended solids and impurities.

Glass Manufacturing: Refined quartz sand with over 99% SiO₂ content is the primary raw material for flat glass and photovoltaic glass. Its purity directly determines the transparency and strength of glass products.

High-Tech Industries: High-purity quartz sand is critical for semiconductor chips, optical fibers, and aerospace materials. In chip manufacturing, it is processed into quartz crucibles and boats to hold silicon wafers during high-temperature processes, where impurity levels must be controlled at ppm (parts per million) levels.

IV. Core Quality Requirements of Quartz Sand: Customization is Key

Quality requirements for quartz sand vary significantly across applications, with key metrics focusing on purity, particle size, impurity content, and physical properties.

Purity: Construction-grade sand requires SiO₂ ≥ 90%, while high-purity sand for semiconductors demands ≥ 99.999%.

Particle Size: Filter media requires uniform size distribution (e.g., 0.8–1.2 mm) for optimal efficiency, whereas ultrafine quartz powder (<5 μm) is suited for coatings and ceramics where smooth texture is critical.

Impurities: Trace metals like iron, aluminum, and calcium impair glass transparency and semiconductor conductivity. High-end applications typically mandate iron content <50 ppm.

Physical Properties: Construction sand must achieve compressive strength ≥60 MPa and clay content <3%, while quartz sand for high-temperature environments must withstand ≥1700°C with excellent thermal stability.

V. Magnetic Separation in Quartz Sand Processing

Common magnetic separation equipment for quartz sand purification includes:

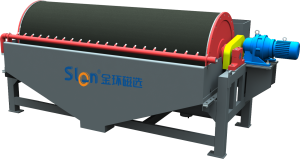

1. LIMS

2. SGTQ Dry LIMS

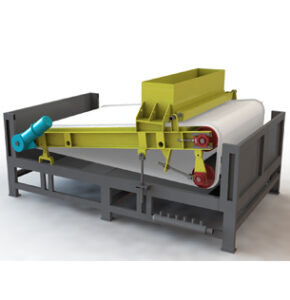

3. Belt Type Magnetic Separator

4. VPHGMS

SLon emphasizes that processing quartz sand requires integrating raw material characteristics with end-use requirements. Only through precise purification techniques, including magnetic separation, flotation, and acid leaching, can true customized production be achieved, unlocking its full industrial value. Whether for standard construction sand or high-purity applications, understanding classification standards, quality requirements, and reserve data from key producing regions remains the fundamental prerequisite for selecting and applying quartz sand effectively.