Heavy Medium Separation Method

Principle

According to Archimedes’ theorem, the particles with a density less than that of the heavy medium will float in the medium, and particles with a density greater than that of the heavy medium will sink in the medium.

Technical Process

The gravity separation process consists of a series of continuous operations, which can be divided into three parts: preparation, separation and product processing.

1. Preparation: a. Crushing and grinding to separate useful mineral monomers; b. Washing and desilming of colloid or clay-rich ores; c. Screening or hydraulic classification to classify the selected ores according to the particle sizes. After the ores are classified, they are selected separately, which is conducive to improving the sorting efficiency.

2. Separation operation is the main link of ore sorting. The separation process can be simple or complex. The simple one consists of unit operations, such as heavy medium separation.

3. Product processing operations, mainly includes concentrate dewatering, tailings transportation and stockpiling.

Main equipment

1. Jigging machine: It uses pulsating water flow to separate mineral particles according to the density, and separates coarse and medium-sized minerals with a large processing capacity and high sorting efficiency.

2. Shaking table: With the help of reciprocating motion of the bed surface and water flushing, the mineral particles are divided into the layers and zones according to the density and particle size, which is suitable for precise separation of fine particles.

3. Spiral chute: The slurry rotates and flows in the spiral chute. The centrifugal force combined with gravity separates the minerals. It is suitable for processing fine-grained low-grade ores without power consumption.

4. Cone concentrator: It is composed of multiple layers of inverted cone-shaped inclined surfaces. When the slurry flows through, the minerals with high density settle inward. It has a large processing capacity and occupies a small area. It is suitable for placer mines.

5. Centrifugal concentrator: High-speed rotation produces a strong centrifugal field, strengthens the sedimentation of fine-grained heavy minerals, recovers fine-grained minerals (such as tungsten and tin), which has high sorting efficiency.

Flotation

1. Principle

Flotation is a method of separating minerals based on the differences in physical and chemical properties of the mineral surfaces.

2. Flotation process

It includes grinding, grading, pulping and flotation roughing, cleaning and scavenging operations. Thereare a grinding and flotation process, a stage grinding and flotation process of segmented grinding-flotation, and a concentrate or middling regrinding and reselection process. The operation of flotation to produce rough concentrate is called roughing; the reselection of rough concentrate is called concentrating; the reselection of tailings is called scavenging. When recovering multiple useful minerals in the ore, the process of flotation of different minerals in sequence is called priority flotation or selective flotation; the process of first floating out all the useful minerals and then separating them is called mixed-separation flotation.

Flotation Equipment

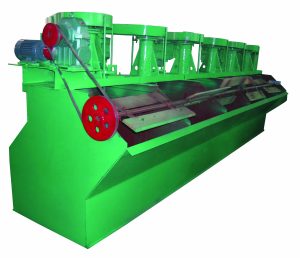

1. Mechanical stirring flotation machine: It generates bubbles and mixes with the slurry through impeller stirring to achieve mineral separation. It has a classic structure and is widely used. It is suitable for the flotation of various minerals.

2. Aerated flotation machine: Air is pressed in from the outside to form bubbles, which reduces impeller wear. The aeration volume is large and stable, and is suitable for processing large amounts of ore and low-grade ore.

3. Hybrid flotation machine: Combining mechanical stirring and external aeration, it has both strong stirring force and stable aeration volume, which improves sorting efficiency and is suitable for complex mineral sorting.

4. Aerated agitator flotation machine: The impeller agitation and external aeration work together. The bubbles are evenly distributed, and the slurry has good suspension, which is suitable for the separation of coarse and fine particle mixed minerals.

5. Gas precipitation flotation machine: It uses pressure changes to cause gas to precipitate from the slurry to form microbubbles. It has significant advantages in sorting fine-grained minerals, which is often used for the sorting of precious metals and fine mud.

Magnetic Separation

1. Principle

It uses the magnetic differences of various ores or materials to separate them under the action of magnetic force and other forces.

2. Typical magnetic separation process

A certain hematite process: stage grinding-gravity separation-strong magnetic separation-reverse flotation process, in which the selection of strong magnetic separation equipment is the key to the success of the process transformation. The obtained indicators: ore grade(30.15%Fe), iron concentrate grade(67.50%) and Fe Iron recovery rate(78.05%).

A certain ilmenite ore process: stage grinding-strong magnetic-flotation process. The obtained indicators: on-site feed TiO2 grade( 6.41%) and strong magnetic-flotation concentrate TiO2 grade (47.02%).

A certain copper-cobalt mine: SLon magnetic separator is used for two-stage separations of one rougher and one cleaner. The obtained indicators: the copper grade of the raw ore(0.9%) , the cobalt grade (0.1%), the copper concentrate grade(6.45%) and the cobalt grade(0.41%).

3. Magnetic separator

SCT low intensity magnetic separator(LIMS): It uses permanent magnets to generate magnetic fields to absorb magnetic particles in minerals. It has a simple structure and low energy consumption. It is suitable for ferrous metal beneficiation and non-metallic iron removal. It is commonly used in the primary stage of mineral processing.

SGTQ dry magnetic separator: It can directly separate dry mineral particles without using water. It is suitable for arid areas or scenes that are sensitive to water resources. It is often used for the separation of coarse-grained minerals such as magnetite and limonite, as well as the removal of impurities from non-metallic minerals.

Vertical ring pulsating high gradient magnetic separator: It adopts vertical rotating ring and pulsating mechanism, combined with high gradient magnetic field, which can efficiently separate fine-grained weak magnetic minerals. When working, the slurry is fed from the bottom, the magnetic particles are adsorbed on the magnetic matrix, and unloaded with the ring rotating to the discharge end, and the non-magnetic particles are discharged from the bottom due to the pulsation. It is characterized by large processing capacity, high separation efficiency and low energy consumption. It is especially suitable for the separation of fine-grained weak magnetic minerals such as hematite and manganese ore, which performs excellently in the deep processing of metal and non-metallic ores.

SJ High Extraction Magnetic Filter: It’s suitable for the purification of non-metallic minerals such as potassium and sodium feldspar, quartz sand, kaolin, nepheline, fluorite, kyanite, talc and so on, as well as the separation of fine-grained metal minerals. This equipment is used in conjunction with the SLon vertical ring pulsating high gradient magnetic separator to produce high-quality, high-value-added non-metallic concentrates.