As an important industrial mineral raw material, quartz sand is widely used in glass, ceramics, electronics, photovoltaics, casting and other fields. However, natural quartz sand often contains impurities such as iron, aluminum, feldspar and mica, which affect its purity and application value. Therefore, it is necessary to remove impurities through a scientific and reasonable purification process to improve the quality of quartz sand. This article will systematically analyze the purification process of quartz sand production line, covering physical method, chemical method and combined process. Combined with the actual production process, we’ll discuss key technologies and equipment selection.

Main methods of quartz sand purification

The purification methods of quartz sand are mainly divided into two categories: physical method and chemical method. In actual production, a combination of multiple processes is often used to achieve the best purification effect.

1.Physical purification method

The physical method mainly separates impurities by mechanical means, which has the characteristics of low cost and good environmental protection, which is suitable for most quartz sand purification needs.

(1) Crushing and screening

Quartz sand raw ore usually needs to undergo multi-stage crushing and screening to meet the particle size requirements of subsequent mineral processing technology.

Coarse crushing: Use a jaw crusher or hammer crusher to crush the raw ore to 20-50mm.

Medium and fine crushing: Use a cone crusher or impact crusher to further crush the ore to 5-10mm.

Grinding: Use a ball mill or rod mill to make the quartz sand particle size reach 0.1-0.5mm for subsequent sorting.

Screening: Use a vibrating screen or hydrocyclone to remove coarse particles and fine mud to ensure uniform particle size.

(2) Magnetic separation to remove iron

Iron impurities (such as magnetite, hematite, limonite and etc.) are the main factors affecting the whiteness and purity of quartz sand. Magnetic separation is the core process for removing iron impurities.

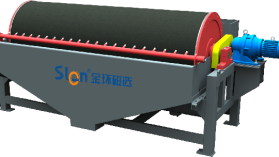

Dry magnetic separation: Suitable for the pre-selection of coarse-grained quartz sand, using a drum type permanent magnetic separator to remove strongly magnetic minerals.

Wet magnetic separation: Suitable for fine-grained quartz sand, using a high gradient magnetic separator (magnetic field strength above 1.0T) to remove weakly magnetic impurities.

Multi-stage magnetic separation: Adopt the process of “rougher-cleaner-scavenger” to improve the iron removal efficiency and reduce the Fe2O content to below 0.05%.

(3) Gravity separation and flotation

Gravity separation: Utilize the density difference between quartz and feldspar and mica, using spiral chutes, shaking tables and other equipment to separate light impurities.

Flotation: By adding hydrofluoric acid, amine collectors and other reagents, feldspar and mica float and quartz settles to improve the purity of SiO2.

2.Chemical purification method

For high-purity quartz sand (such as electronic and photovoltaic grade), chemical methods are required for further purification.

Acid leaching: Use hydrochloric acid, sulfuric acid or oxalic acid to dissolve metal oxides such as iron and aluminum.

High-temperature chlorination roasting: Pass chlorine gas at a high temperature of more than 1000℃ to volatilize impurities, which is suitable for the production of ultra-high purity quartz sand.

Key technologies and equipment selection for quartz sand purification

1.Optimization of magnetic separation process

Magnetic separation is the core link of quartz sand purification, and appropriate equipment should be selected according to the characteristics of impurities:

Strongly magnetic minerals (such as magnetite): use ordinary drum type permanent magnetic separator (0.3-0.5T).

Weakly magnetic minerals (such as hematite and limonite): SLon vertical ring high gradient magnetic separator or strong magnetic field magnetic separator (above 1.0T) is required.

2.Optimization of flotation process

Agent selection: hydrofluoric acid activates feldspar, and amine collectors promote the floating of mica.

pH value control: maintain an acidic environment (pH=2-3) to improve flotation efficiency.

3.Combined process application

Magnetic separation+flotation: First, remove iron by magnetic separation, then remove feldspar and mica by flotation, which is suitable for medium-purity quartz sand.

Magnetic separation+acid washing: After magnetic separation, acid leaching is used to further reduce the iron content, which is suitable for high-purity quartz sand.

SLon Vertical Ring High Gradient Magnetic Separator–Quartz Sand Classic Case