Among various minerals, ilmenite holds a crucial position due to its unique chemical composition and wide range of applications. It is not only a key source of titanium, but also plays an indispensable role in numerous areas of modern industry, including metallurgy, chemical engineering, and aerospace.

1.Chemical Composition of Ilmenite

Ilmenite has the chemical formula FeTiO3, with a theoretical TiO2 content of 52.66% and an iron content (as FeO) of 47.34%. Ilmenite typically appears iron-black or steel-gray. Its streak is steel-gray or black, and if it contains hematite inclusions, the streak may appear brown or brownish-red. Its luster is metallic to semi-metallic, opaque, and lacks cleavage. Its hardness ranges from 5 to 6.5 on the Mohs scale. Its specific gravity is between 4 and 5, and it is weakly magnetic. Under a polarizing microscope, ilmenite appears dark red and is opaque or slightly transparent.

2.Distribution of Ilmenite in China

China is rich in ilmenite resources, with TiO2 reserves of 428 million tons, ranking first in the world. The main supply bases are distributed in Sichuan, Hebei, Yunnan, Hainan, Guangdong, Guangxi, Shanxi, Shandong, Shanxi, Henan and other places, among which Sichuan has the most considerable reserves.

3.Industrial Application of Ilmenite

Titanium Metal Production: Titanium and its alloys are widely used in the military and aerospace industries due to their excellent properties, including low density, high strength, corrosion resistance, high temperature resistance, and excellent plasticity.

Titanium Dioxide Production: Ilmenite is one of the main raw materials for titanium dioxide production.

Other Applications: In the chemical industry, titanium is widely used in the synthetic fiber industry, petrochemical industry, fertilizer industry, and alkali industry due to its excellent corrosion resistance. In the medical field, titanium is a preferred metal medical material due to its excellent biocompatibility.

4.Commonly Used Magnetic Separation Equipment for Ilmenite

Vertical Ring Pulsating High Gradient Magnetic Separator(VPHGMS)

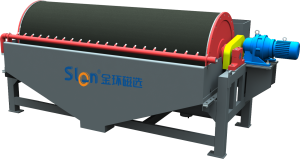

Wet Drum Magnetic Separator(LIMS)

5.Application Cases

Longbai Sichuan Mining and Metallurgy Co., Ltd.

Currently, 14 SLon-4000 VPHGMS are used to recover ultrafine ilmenite from existing production tailings, increasing annual production of 120,000-150,000 tons of titanium concentrate with a TiO2 grade of 46% or higher.

The comprehensive performance achieved by the VPHGMS (roughing, cleaning, scavenging) process is as follows: feed TiO2 grade of 7.52%, concentrate TiO2 grade of 16.83%, tailings TiO2 grade of 3.65%, concentrate yield of 29.36%, and concentrate recovery rate of 65.71%.

Panzhihua Iron & Steel Mining Co., Ltd.

On-site magnetic separation is divided into coarse and fine-grained separation.

Fine-grained magnetic separation applies SLon VPHGMS in a one-roughing-one-scavenging and one-cleaning-one-scavenging process.

Coarse-grained magnetic separation uses a single roughing process, and the coarse concentrate is graded and regrinded before a one-cleaning-one-scavenging process.

The company has an annual ore processing capacity of approximately 7.5 million tons and produces approximately 600,000 tons of titanium concentrate. The TiO2 grade of the ore entering the separation is 9.85%, the concentrate is 47.5%, and the tailings are 6.58%. The concentrate yield is 7.72%, the concentrate TiO2 recovery is 37.22%, and the beneficiation ratio is 12.94.