Ultra-large SLon-5000 VPHGMS have been Applied to the Beneficiation of Ilmenite in Anning, Sichuan

1.Equipment Structure and Working Principle

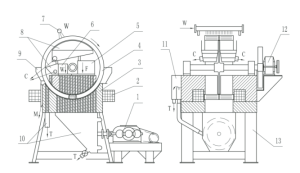

The core structure of SLon-5000 VPHGMS, as shown in Figure 1, mainly consists of an ultra-large electromagnetic system, a vertical separation ring, a pulsating mechanism, a drive system, and feeding and discharging boxes. To overcome the limitations of ultra-large equipment in manufacturing, transportation, and installation, this equipment creatively adopts a split-frame electromagnetic system structure, decomposing the massive magnetic system into modular units. This not only significantly reduces the volume and weight of individual components but also greatly facilitates on-site installation and subsequent maintenance.

Working Principle: During operation, the slurry (F) is fed into the separation ring (4) placed in a strong magnetic field zone via the feeding box (5). Weakly magnetic minerals are captured by the magnetized rod matrix and rotate with the separation ring to the top non-magnetic field area, where they are washed off by the top flushing water (6) and become magnetic products. Non-magnetic minerals, under the combined action of gravity and pulsating fluid force, pass through the gaps between the rod matrix and enter the tailings box (10) for discharging, becoming non-magnetic products.

Fig. 1 Schematic diagram of super-large SLon-5000 VPHGMS

1-Pulsating mechanism; 2-Energizing coil; 3-Magnetic yoke; 4-Working ring; 5-Feeding box; 6-Wash water box; 7-Concentrate flush; 8-Concentrate box; 9-Middling chute; 10-Tailing box; 11-Slurry level box; 12-Ring driver; 13-Support frame; F-Feed; W-Water; T-Tailings; M-Middlings; C-Concentrate

2.Main Technical Parameters of SLon-5000 VPHGMS

The core technical parameters of the first ultra-large SLon-5000 VPHGMS are shown in Table 1. Its most significant technical features are its ultra-large separation ring diameter and processing capacity, which has outstanding energy-saving advantages.

|

Model |

SLon-5000 |

|

Ring diameter /mm |

5000 |

|

Background field /T |

0-1.8 |

|

Feed density /% |

10-40 |

|

Slurry throughput /(m3/h) |

900-1350 |

|

Ore throughput /(t/h) |

450-950 |

|

Rated power /kW |

0-260 |

|

Flushing water consumption /(m3/h) |

450-680 |

|

Cooling water consumption /(m3/h) |

7-10 |

|

Dimensions (L*W*H) /mm |

9900×8000×10100 |

3.Panzhihua Anning Titanium Tailings Recycling

The Panxi region is China’s largest vanadium-titanium magnetite base, whose beneficiation and smelting processes generate massive amounts of tailings. In the comprehensive tailings discharged by Sichuan Anning Iron & Titanium Company, the average grades of TFe and TiO2 are approximately 12.1% and 4.5%, respectively. Titanium mainly exists in the form of finely disseminated ilmenite, with particles of -0.074 mm accounting for over 60%. The mineral composition is complex, classifying it as a typical “low-grade, fine-grained, and difficult-to-recover” resource. Small-scale SLon VPHGMS used in production had a small single-unit processing capacity (<300 t/h), resulting in low recovery efficiency for fine ilmenite and high power consumption per ton of ore, leading to a significant loss of titanium resources in the tailings.

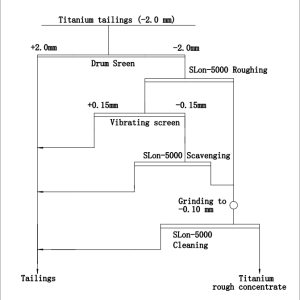

To solve this technical challenge, SLon introduced three ultra-large SLon-5000 VPHGMS, constructing a new production line with a “coarse and fine classification – sequential separation using SLon-5000 VPHGMS with coarse and fine rod matrix” process (Figure 2, processing 600 tons of titanium tailings per hour). In this new process, SLon-5000 VPHGMS efficiently pre-enriches the total tailings from the original high intensity magnetic separation and flotation (titanium tailings in Figure 2), removing most of the gangue and slime. Since its commissioning in April 2024, the new process based on SLon-5000 VPHGMS has been able to stably produce titanium rough concentrate with a TiO₂ grade of over 13.06% from titanium tailings with a TiO₂ grade of approximately 4.5%, achieving a TiO₂ recovery rate of 44.11% and a daily output exceeding 300 tons. This rough concentrates are then further refined through flotation to ultimately obtain marketable titanium concentrate with a TiO₂ grade of over 43.00%.

The ultra-large SLon-5000 VPHGMS, with its powerful high gradient magnetic field and pulsating flow field, achieves highly efficient recovery of fine ilmenite, reducing the titanium tailings grade to 2.5-3.0% (of which approximately 1.5% is titanium-bearing gangue minerals), elevating the efficiency of strong magnetic pre-enrichment to a new level. Calculations show that the new process can process 600 tons of titanium tailings per hour, with the power consumption of 0.74 kWh per ton of tailings and water consumption of 2.4 m³/h. This results in annual electricity savings of approximately 3 million kWh, equivalent to saving 963 tons of standard coal and reducing CO2 emissions by 2503 tons, demonstrating significant technical, economic, and environmental benefits. This application case successfully constructs a new circular economy model of “low-grade resource value-added processing – solid waste reduction – low-carbon production process,” providing an important engineering demonstration for the development and utilization of large quantities of stockpiled and discharged hematite, manganese ore, and other difficult-to-process weakly magnetic minerals in China.

-

Ilmenite HGMS for Tailings RecyclingIlmenite is always used as the raw material for titanium powder produc…

Ilmenite HGMS for Tailings RecyclingIlmenite is always used as the raw material for titanium powder produc… -

Ilmenite HGMS for Minieral SeparationIlmenite is always used as the raw material for titanium powder produc…

Ilmenite HGMS for Minieral SeparationIlmenite is always used as the raw material for titanium powder produc… -

WET HIGH INTENSITY MAGNETIC SEPARATOR(WHIMS)SLon has finished the design of the largest SLon-6500 VPHGMS(WHIMS), w…

WET HIGH INTENSITY MAGNETIC SEPARATOR(WHIMS)SLon has finished the design of the largest SLon-6500 VPHGMS(WHIMS), w…