SLon-500 and SLon-750 lab-scale Wet High Intensity Magnetic Separator is capable of continuous beneficiation to simulate industrial practice.

Lab-scale Industrial HGMS

Product Features

- Low voltage, high current and low current density.Internal water cooling and double circulation cooling mode stable magnetic field. Equipment operation rate is up to 98%;

- Pulsation mechanism design could improve the separation efficiency;

- Optimized magnetic system design, optimal arrangement and combination of magnetic matrix, background field intensity up to 1.7T. vertical rotation. Reverse flushing achieve magnetic matrix is not easy to block;

- Wide separation range: upper limit 6mm, lower limit 2~10μm;

- Equipped with coil pipeline cleaning system, easy for coil daily maintenance. Coil designed life is up to 10 years.

Product Details

Technical Parameters

| Technical Parameters | |||||||

| Parameters | SLon-500 | SLon-750(Ⅰ) | SLon-750(Ⅱ) | SLon-500 | SLon-500 | SLon-750(I) | SLon-750(II) |

| Ring diameter /mm | 500 | 750 | 750 | 500 | 500 | 750 | 750 |

| Ring speed /(r/min) | 0.3~3 | 0.3~3 | 2.5~3 | 0.3~3 | 0.3~3 | 0.3~3 | 2.5~3 |

| Feed size /(mm),(-74μm%) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) | -1.3(30~100) |

| Feed density /% | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 |

| Slurry throughput /(m3/h) | 0.25~0.5 | 0.5~1.0 | 5~10 | 0.2~0.5 | 0.2~0.5 | 0.5~1.0 | 5~10 |

| Ore throughput /(t/h) | 0.03~0.125 | 0.06~0.25 | 2~4 | 0.03~0.125 | 0.03~0.125 | 0.06~0.25 | 2~4 |

| Background field /T | 1/1.1 | 1/1.1 | 1/1.1 | 1.3 | 1.7 | 1.3 | 1.5 |

| Rated current /A | 1200 | 1100 | 800 | 1700 | 1900 | 1300 | 1350 |

| Rated voltage /V | 11 | 16 | 15 | 17 | 25 | 22 | 25 |

| Rated power /kW | 13 | 17 | 12 | 29 | 48 | 29 | 35 |

| Ring motor /kW | 0.18 | 0.55 | 0.75 | 0.18 | 0.18 | 0.55 | 0.75 |

| Pulsating motor /kW | 0.37 | 0.75 | 1.5 | 0.37 | 0.37 | 0.75 | 1.5 |

| Pulsating stroke /mm | 0~30 | 0~30 | 0~20 | 0~30 | 0~30 | 0~30 | 0~20 |

| Pulsating speed /(per/min) | 0~400 | 0~400 | 0~300 | 0~400 | 0~400 | 0~400 | 0~300 |

| Water pressure /MPa | 0.1~0.2 | 0.1~0.2 | 0.1~0.2 | 0.1~0.2 | 0.1~0.2 | 0.1~0.2 | 0.1~0.2 |

| Flushing water consumption /(m3/h) | 0.75~1.5 | 0.75~1.5 | 5~8 | 0.75~1.5 | 0.75~1.5 | 1.5~2 | 6~10 |

| Cooling water consumption /(m3/h) | 0.75~1.5 | 0.75~1.5 | 1~2 | 1~1.5 | 1~1.5 | 0.75~1.5 | 1~2 |

| Max part weight /t | 0.3 | 0.6 | 1 | 0.5 | 0.5 | 0.6 | 1.3 |

| Dimensions (L*W*H) /mm | 1800×1400×1350 | 2100×1400×1700 | 2300×1800×1750 | 1850×1450×1350 | 1850×1450×1400 | 2050×1310×1750 | 2300×1800×1830 |

Recommended Products

-

WET HIGH INTENSITY MAGNETIC SEPARATOR(WHIMS)SLon has finished the design of the largest SLon-6500 VPHGMS(WHIMS), w…

WET HIGH INTENSITY MAGNETIC SEPARATOR(WHIMS)SLon has finished the design of the largest SLon-6500 VPHGMS(WHIMS), w… -

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)…

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)… -

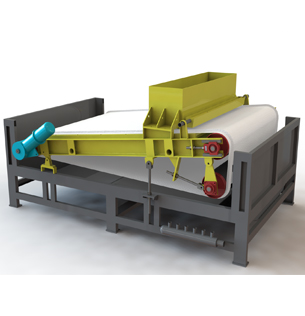

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera…

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera… -

HIGH EXTRACTION MAGNETIC FILTER(HEMF)High Extraction Magnetic Filter(HEMF) is suitable use for processing f…

HIGH EXTRACTION MAGNETIC FILTER(HEMF)High Extraction Magnetic Filter(HEMF) is suitable use for processing f…

Leave a Message

If you are interested in any product, please contact us. We will introduce our products to you in more detail