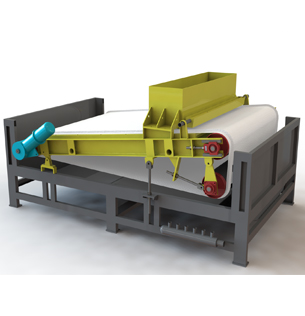

The oxidized iron ore mainly includes hematite, specularite, limonite, siderite and etc. in China. All of them are weakly magnetic ores, which are characterized by large reserves, low grade and fine disseminated particle size. Besides, most of them are difficult to be ground and selected. However, there’s an increasing demand for high-grade iron concentrates in iron and steel smelting industry. In order to meet the huge market need, through continuous innovation and research, SLon has developed a new type Iron Ore HGMS with different specifications and magnetic intensity according to the mineral features.

After years of unremitting improvement and innovation, Iron Ore HGMS has the following characteristics:

1. Large handling capacity;

2. Under the premise of ensuring high grade, the recovery rate can reach up tomore than 70%.

3. According to the ore size, characteristics, concentration and so on, medium boxcan be customized, in order to achieve theoptimum beneficiation index;

4. Equipped with unique cooling water recycling device, it greatly reducesthe consumption of water.

With the application of Iron Ore HGMS, a large number of fine sized oxidized iron ores have obtained higher beneficiation indexes. For example, Essar Steel in India, has purchased 10 sets SLon-2500 Iron Ore HGMS and adapted the processing technology of one roughing and one scavenging with a raw ore grade of 59.77%. The comprehensive iron concentrate grade is 65% and the recovery rate reaches to 93.86%. In the Sierra Leone project, 22 sets SLon-2500 Iron Ore HGMS have been introduced. With the same processing techniques, The grade of comprehensive iron concentrates is increased from 34.94% to 67.1%, and the recovery rate is 74.74%. So far, over 2000 Iron Ore HGMS have been applied to oxidized iron ore concentrating plants all over the world, which are highly praised by customers.