The Applications of SLon Silica Sand Magnetic Separator in Malaysia

As the indispensable basic materials in the high-tech field, high-purity silica sand is applied more and more widely.

High-purity silica sand, as its name indicates, is quartz with few impurities and high purity (SiO2 content is more than 99.9% and Fe2O3 is less than 100ppm), which is mainly used in high-tech fields such as communications, electronics, photovoltaics and etc.. It’s also of the highest added value among all quartz products.

Nowadays, the demand for both the quantity and quality of silica sand is increasing in the society. However, natural ores always contain a lot of harmful impurities such as iron and titanium. How to improve its purification process and obtain high purity silica sand is crucial.

There’s a large amount of silica sand resources with low iron content somewhere in Pahang, Malaysia, which enjoys a high reputation of “Quartz Town”. The silica sand in this area is white and off-white powder in appearance. After crushing and grinding, its particle size is evenly distributed in the range of 75~100 microns. The concentrates with Fe2O3 content of 400~500ppm produced by traditional simple processing techniques such as “crushing- stone grinding – shaking table removing heavy minerals – permanent magnetic separator iron removal- classifying-final product dewatering” is difficult to satisfy the demand of high-end customers. In industrial production, the raw ores of quartz contains iron, titanium and other impurities. Its embedded particle size is fine and the occurrence state is poor. The impurities are weakly magnetic, such as iron carbonate, iron silicate, rutile (the main source of titanium), which is easily wrapped or associated with the quartz. In addition, the surface grooves often adhere to impurities such as yellow skin and the particle size of the final product cannot be ground too fine. All of these factors greatly increase the difficulty of purification.

At the beginning of 2019, the introduction of SLon Wet High Intensity Magnetic Separator(WHIMS) has profoundly changed the whole industrial situation in local area. In view of the mineral composition characteristics, SLon has launched a customized silica sand WHIMS after continuous experimental research and technical transformation. First of all, for the weakly magnetic impurities embedded with fine particle size, our technical engineers adjust the magnetic system and structure, so that the background magnetic intensity can reach up to 1.8T and the actual working magnetic intensity is close to 2.0T, which provides strong guarantee on the separation of weakly mags. Secondly, as the quartz is relatively coarse and shall not be ground too finely, SLon has added special design in the separation area and channel to ensure the smooth flow of the slurry. Finally, in order to reduce the secondary pollution in the sorting process and the mixing of mechanical iron into the slurry, we has also made protective treatment on the slurry passing area. So far, the practical applications have proved that this new type of silica sand WHIMS, combined with the beneficiation process of “grinding – scrubbing – two stage silica sand WHIMS “, can produce final products with Fe2O3 content of 90ppm and yield rate of 85% in general. The quality improvement contributes to the soaring price of silica sand products, which brings considerable benefits to the local related companies.

The physical separation process is not only simple to operate, but also eco-friendly without any harmful beneficiation chemicals, which opens up new ideas for the quartz purification industry and creates considerable economic, social and environmental benefits for enterprises. It has won unanimous praise from users.

-

PROCESSING LINE FOR FLEDSPAR AND SILICA SAND CONCENTRATORAs the inventor of Vertical Pulsating High Gradient Magnetic Separator…

PROCESSING LINE FOR FLEDSPAR AND SILICA SAND CONCENTRATORAs the inventor of Vertical Pulsating High Gradient Magnetic Separator… -

Silica Sand HGMS for Non-metallic PurificationSilica sand, as an important industrial mineral raw material, is widel…

Silica Sand HGMS for Non-metallic PurificationSilica sand, as an important industrial mineral raw material, is widel… -

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)…

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)… -

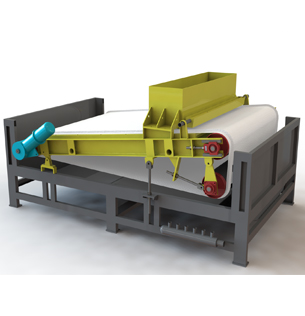

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera…

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera… -

HIGH EXTRACTION MAGNETIC FILTER(HEMF)High Extraction Magnetic Filter(HEMF) is suitable use for processing f…

HIGH EXTRACTION MAGNETIC FILTER(HEMF)High Extraction Magnetic Filter(HEMF) is suitable use for processing f…