Feldspar, as one kind of aluminum silicate minerals containing calcium, sodium, potassium, is an important industrial raw material ceramic. With the higher requirement for the quality of ceramic products in society, the whiteness of feldspar is low, produced by the traditional processing technology, like “Crushing+Ball Milling+Weak Magnetism”, which is far from the demand of the market.

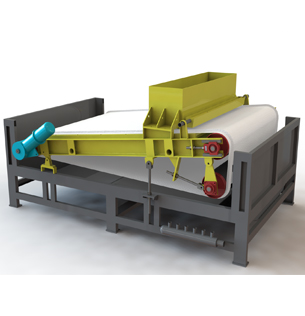

As we all know, the harmful materials occurring in feldspar mainly include weakly magnetic iron minerals, mica, tourmaline, garnet and etc., with fine dissemination granularity and poor occurrence state, whose contents directly influence the whiteness of feldspar. Based on these features, SLon has introduced the Feldspar HGMS, through continuous experimental research and technical transformation. First of all, as for the weakly magnetic impurities with fine particle size, SLon has specially designed the magnetic system structure of original HGMS, so that the background magnetic field strength of the equipment can reach up to 1.8T. Besides, the contact part of the ore bucket is made of stainless steel to reduce the pollution of mechanical iron mixed with the concentrates. For fine-grained feldspar minerals (particle size less than 200 mesh), our technicians have developed High Extraction Magnetic Filter (HEMF) with the maximum background field strength of 1.8T. It adapts medium fine mesh and bristles, as well as a stronger magnetic to effectively remove the finer and less magnetic iron impurities. At the same time, it uses pneumatic butterfly valve control and PLC automatic control, which can guarantee the operation of machines. So far, a lot of practical applications have proved that Feldspar HGMS and HEMF, combined with the processing technique of “Crushing + Grinding + Feldspar HGMS for two-time separation + HEMF”, can obtain the feldspar concentrates with a whiteness of 70% and its yield rate can reach up to 80%. The high-quality products have directly brought considerable benefits to mining enterprise. In some parts of India, like Morbi, for example, the process has increased the whiteness of the raw materials from 40 to 90, and created a new idea to the treatment of feldspar in the region. The separation process is not only simple to operate, but also produces little environmental pollution without any chemical agents, which belongs to pure physical mineral processing technique. More and more mining enterprises have adapted this method. And SLon Feldspar HGMS has won a great many unanimous praises from customers.