500TPD Specularite Beneficiation Project in Jiangxi

Project Name:500TPD Specularite Beneficiation Project in Jiangxi

Location:Jiangxi, China

Mineral:Specularite

Capacity:500TPD

Main Equipment:SLon WHIMS+SLon Centrifugal Separator

Processing Technology:Magnetic separation+Gravity Separation

There is a specularite concentrator in Jiangxi, whose raw materials are lean with only 22.63% TFe. The iron minerals are dominated by specularite and a small amount of magnetite, with the only 3% mags rate. Main gangue minerals are quartz, mica, chlorite, garnet and apatite.This mine is characterized by the scale crystal structure, followed by other granular crystal structure. All these lead to weak magnetism, which makes it difficult to separate by magnetic separation alone, and makes a high requirement for technological process.

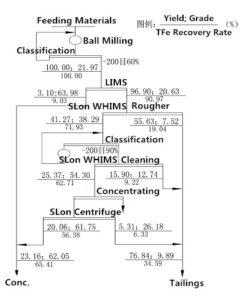

Faced with challenges, we chose to overcome them and found that the technical process of strong magnetic separation and gravity separation can effectively solve the problem after a large number of studies. Therefore, since the end of 2010, we have cooperated with the plant. In the first stage of grinding, the ores are ground to about -200 mesh accounting for 60%. Prior to the strong magnetic separation, the feeding materials travel over the weak magnetic machines to remove magnetite concentrates. And then the metal mix will pass through the Wet High Intensity Magnetic Separator(WHIMS) to cast parts of low-grade ores. The hydrocyclone produces a separation by exploiting the difference in gravity between various materials. This step needs to repeat and the materials go through the second stage of grinding. Followed by these, the processed materials of -200 meshes(90%) will enter the second stage of SLon WHIMS for concentration before SLon centrifuges. The concentrates obtained are finally selected through gravity separation by SLon centrifuges. The tailings of the second strong magnetic separation and the centrifuge are discharged. The whole process are complex, and yet the result is remarkable. The grade of the end products is 62.05% and the recovery rate of iron concentrates reaches up to 65.41%, which created great economic benefits for the plant.

The technical process is not only applied to this kind of minerals, but also the weak magnetic ores. Its successful application plays an important role in the comprehensive utilization of weak mags.

-

Iron Ore HGMS for Mineral SelectionThe oxidized iron ore mainly includes hematite, specularite, limonite,…

Iron Ore HGMS for Mineral SelectionThe oxidized iron ore mainly includes hematite, specularite, limonite,… -

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera…

BELT TYPE MAGNETIC SEPARATORIt's suitable for iron removal and purification of non-metallic minera… -

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)…

WET DRUM MAGNETIC SEPARATOR(LIMS)Wet drum magnetic separator aka low intensity magnetic separator(LIMS)…